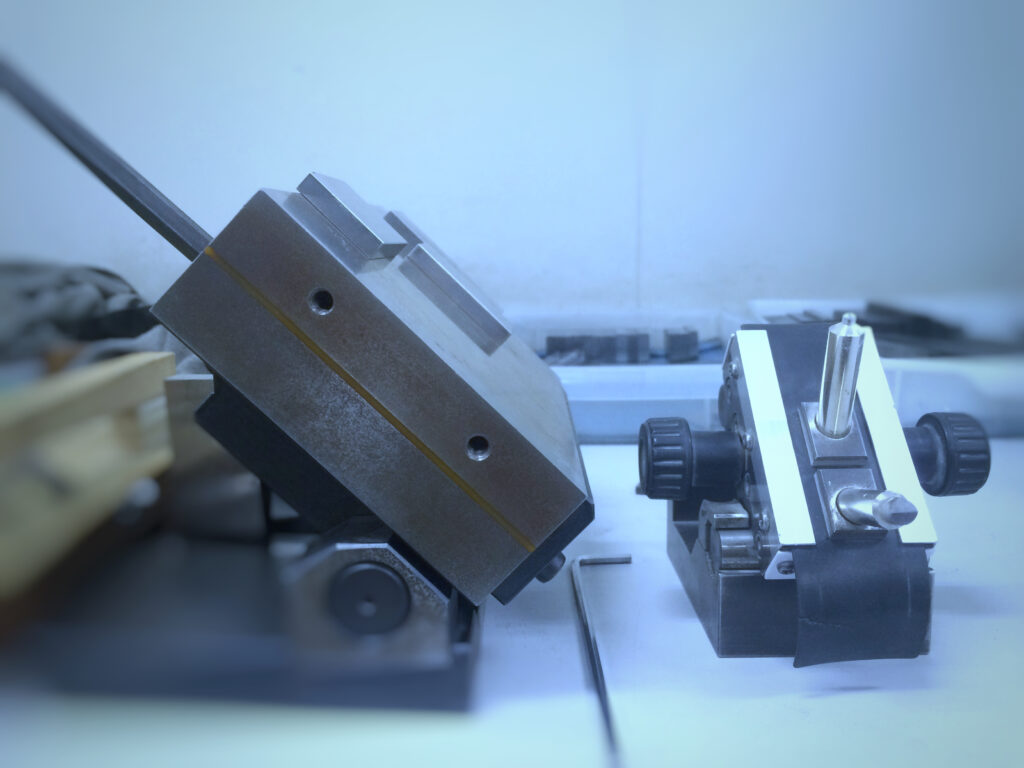

Electromagnetic Chuck Applications and Considerations

Electromagnetic chucks consist of a magnetic base, coils, and an electronic control unit that generates a magnetic field when electricity is applied. This magnetic field securely holds the workpiece in place on the chuck’s surface. The strength of an electromagnetic chuck hold can be adjusted by varying the electric current, providing versatility for machining different materials and part sizes.

Key Features and Benefits

- Variable Holding Power: One of the main advantages of electromagnetic chucks is the ability to adjust the magnetic force. This allows for the precise control of the holding power depending on the machining operation, ensuring optimal grip without damaging the workpiece.

- Uniform Clamping Pressure: These chucks apply even clamping pressure across the workpiece, reducing the risk of distortion, particularly in thin or delicate parts. This uniform pressure is crucial for maintaining the integrity of precision components.

- Enhanced Safety and Convenience: With electromagnetic chucks, there is no need for physical clamps or fixtures, which can obstruct the machining tool’s path. This not only enhances safety by reducing manual handling but also improves access to the workpiece, allowing for more efficient machining processes.

- Rapid Setup and Changeover: Electromagnetic chucks significantly reduce setup and changeover times compared to traditional clamping methods. This efficiency is particularly beneficial in high-volume production where time savings directly translate to increased throughput.

- Versatility: These chucks are suitable for a wide range of machining applications, from surface grinding to heavy milling. Their ability to hold various shapes and sizes of ferrous materials makes them invaluable tools in diverse manufacturing settings.

Applications in Industry

Electromagnetic chucks are widely used in both the aerospace and automotive industries, where precision machining of complex parts is essential. They are also prevalent in tool and die making, metal fabrication, and any sector requiring the machining of ferrous materials.

Considerations and Limitations

While electromagnetic chucks offer numerous advantages, there are considerations to bear in mind. They require a constant power supply to maintain the magnetic hold, which can be a limitation in environments where power interruptions are common. However, modern control units are designed to ensure safety and prevent accidental deactivation. In such application environments, electro-permanent magnetic chucks may be considered as a preferable alternative

Technological Advancements

Advancements in electromagnetic chuck technology have led to the development of more sophisticated control systems, allowing for finer control of the magnetic field and even programmable profiles for different workpieces. Additionally, improvements in materials and design have enhanced the durability and reduced the energy consumption of these chucks.

Conclusion

As electromagnetic chucks continue to revolutionize precision machining with their unparalleled efficiency and flexibility, staying at the forefront of this technology is key for any manufacturing operation looking to enhance its capabilities. To explore the latest in electromagnetic chuck technology and how it can transform your machining processes, consider reaching out to Brisc Magnet. Their expertise in advanced workholding solutions can provide you with the tools you need to elevate your production to new heights of precision and efficiency. Contact Brisc Magnet today to learn more about their electromagnetic chuck offerings and take the first step towards optimizing your manufacturing workflow.