The Different Types of Magnetic Workholding Systems

Magnetic workholding systems are key players in the manufacturing world, enabling precision and efficiency during machining. The setups leverage magnetic fields to securely hold ferrous parts, offering a clean, clamp-free environment for operations. Having a range stretching from simple magnetic plates to sophisticated electro-permanent and modular configurations, these products are designed to meet the varied demands of modern machining tasks. The variety of magnetic workholding systems enables a solution for virtually any scenario, balancing ease of use with the flexibility needed for quick changes and high precision.

Magnetic Chucks

These devices use permanent magnets, electromagnets, or a combination to secure workpieces. Ideal for grinding, milling, and turning, chucks come in various shapes for different applications. Their ease of use and quick setup make them popular.

Magnetic Blocks and Plates

Magnetic Blocks and Plates offer simplified solutions, providing flat, magnetized surfaces ideal for grinding or inspection tasks. Blocks can be combined to accommodate larger workpieces, while plates efficiently handle multiple pieces simultaneously. Their versatility in accommodating various sizes and geometries is a notable advantage.

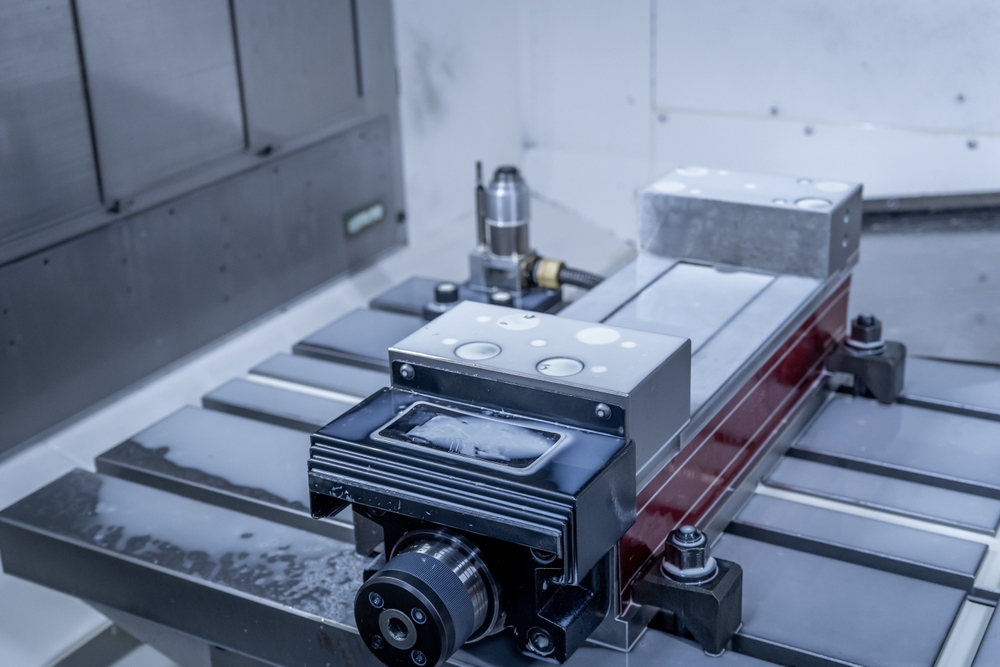

Magnetic Vises

Combining magnetic force with the physical structure of mechanical vises, these tools offer quick setup and are ideal for CNC machining centers. They provide the quick, repeatable clamping necessary for batch production,

Modular Workholding Systems

These adaptable systems comprise magnetic components that can be reconfigured for various jobs, making them perfect for shops with frequently changing needs. Highly versatile, the setup time can be longer as the configuration needs to be adjusted for each new job.

Electro-Permanent Magnetic Systems

Merging the best of permanent and electromagnetic technologies, these systems use a burst of electricity to switch on or off, maintaining their hold without continuous power. This combination offers a secure clamping mechanism that’s safe even during power outages.

Magnetic Tombstone

Magnetic Tombstone Workholding chucks are designed specifically for horizontal machining and mold making tasks. Unlike traditional CNC workholding fixtures, these magnetic solutions ensure uniform support for your workpiece across a larger single area. By freeing up all five sides of your workpiece, they enable you to machine the entire profile of the part in a single setup, streamlining your manufacturing process.

Contact Brisc Magnet Today

The choice of magnetic workholding system depends on the specific needs of the machining operation, including the shape and material of the workpiece, the type of machining being performed, and the desired balance between setup flexibility and clamping strength. Each system brings its own set of advantages to the table, from the simplicity and ease of use of magnetic chucks to the adaptability and configurability of modular systems. Understanding these differences is key to selecting the most appropriate magnetic workholding solution for any given manufacturing objective context.

For tailored magnetic workholding solutions that meet your specific manufacturing needs, consider contacting Brisc Magnet for our expertise and range of options.